furnace and duct cleaning business for sale

We use only the best materials. Pringle air duct cleaning trucks and equipment have helped grow this industry for over 65 years. Our low entry level truck price has helped people get into the air duct cleaning business and thrive since the beginning. Now with our newest Pringle truck there is absolutely no reason to look anywhere else. I guarantee you will agree this is the best truck on the market! The New Pringle MPV-13 and MPV-15 Made of mostly stainless steel including; all floors, lower panels, dirt box, and doors. The Pringle MPV-13 and MPV-15 have optional roll up doors as well. All non -roll up doors are made with stainless steel bolt on hinges that will never require replacement. Not only did we use the best materials we also made it a snap to maintain and work on if the need arises. Easy access to bearings, compressor, and fan will make this truck a snap to work on. With enough room to carry a portable unit, hundreds of feet of hose, and all the accessories you could possibly want this is the ultimate air duct cleaning machine.

The original Pringle truck is the truck that became the standard by which all others are measured. Manufactured for over 65 years, there have been many improvements, including: Enclosing the rear compartment, removing the lower rear compartment increasing hose storage All stainless steel lower sheet metal option Moved rear hold down support for much easier access to compressor and belts We have also added special accessory options over the years including: Top doors, tubular drive shaft, hitch rear bumper, hose reel, and saddle toolboxes. Our unit can be attached to all cab and chassis’s one ton and larger. After 65 years, there is still no more powerful air duct cleaning truck on the market. With a base price of under $75,000 nobody else in the industry even comes close. Contact us now for details! Duct Cleaning > Informational Resources > Patented Duct Cleaning Process Abatement Technologies’® Patented HEPA-AIRE® Duct Cleaning Process Source Removal and Capture Provides Complete Cleaning and Decontamination

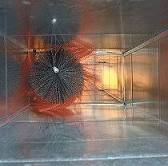

The definition of source removal duct cleaning using the patentedAbatement Technologies’ HEPA-AIRE cleaning process is as follows: Clean the air conveyance system using Abatement’s AIRE-SWEEP® Compressed Air Tools and DUCT-PRO® Mechanical Agitation Brush System to dislodge dirt and other contaminants from the ductwork and other HVAC components. Use a powerful Abatement HEPA-AIRE, HEPA-filtered Portable Power Vacuum to place the section of the duct system being cleaned under negative pressure, pull dislodged contaminants out of the duct system and capture them. A conventional HVAC duct system consists of a supply system of ducts to carry heated or cooled air from the furnace/air conditioner (air handler) to various parts of the home or building, and a return duct system to bring fresh air back to the air handler to be heated or cooled again. network consists of main ducts, which carry air to smaller branch runs,

which in turn carry air to the desired locations. The return network works State-of-the-Art Source Removal Duct Cleaning Process

best vacuum cleaner for carpet cleaning in india The HEPA-AIRE process utilizes an Abatement HEPA-AIRE Portable Power Vac in tandem with a specially designed AIRE-SWEEP Portable Air Compressor and Agitation

easy way to clean timber blinds Tools for efficient state-of-the-art source removal duct cleaning.

air duct cleaning after remodeling This method enables professional duct cleaners to remove contaminants from all parts of the duct system, regardless of location or type of duct. it is simple to perform and requires only a limited amount of access holes.

Here’s how it works: The supply and return networks are “zoned,” or separated, so they canThis is typically done by removing the furnace filter, inserting it into a plastic bag and reinserting it into An access hole is cut into the supply plenum and the flex duct from the HEPA-AIRE Vacuum inlet is connected to the plenum with a quick-connect attachment collar. creates high velocity air movement within the supply ductwork to transport loosened dirt and contaminants out of the ductwork and into the vacuum's filtration/collection system. Each branch is cleaned separately starting with the branch farthestThe register and boot areas are blasted with compressed air from the AIRE-SWEEP Compressor using the special air booster gun to push any dirt or debris into the branch run. The branches are then cleaned by feeding the Forward AIRE-SWEEP Assembly down each branch run to push dirt and debris forward into the main run.

The Reverse AIRE-SWEEP Assembly can also be used to clean branch runs if access at the main supply Agitation devices such as the AIRE-SWEEP Power Brush, Duct Whip or Power Rod System are used when needed to dislodge caked on debris from inside duct surfaces. The main duct run is then cleaned. First, one-inch diameter access holes must be cut into the duct every 25 feet. Devices and an AIRE-SWEEP Assembly are used to dislodge debris accumulatedThe loosened debris is pulled or pushed toward the HEPA-AIRE Portable Power Vacuum and captured in its multi-stage filtration/collection Once the supply side of the system has been completely cleaned, the return duct system is cleaned using the same method. The coil, motor and blower and blower compartment can be cleaned. Once the entire cleaning process is completed, all access holes are completely closed with the efficient CAPLUGS® and cover plates are installed over the access holes.